Choosing frame materials

External glazed windows and doors need a frame that is durable, strong and weather-tight. Timber, aluminium, and uPVC are among our mostly commonly used framing materials, and each has its pros and cons.

Aluminium

Light and durable, aluminium is a popular choice for framing in both residential and commercial buildings. Frames are typically factory-assembled to order, and used in retrofits or new builds. Aluminium doesn’t require regular repainting, so it needs less cleaning and maintenance than timber frames, which helps reduce its overall cost over a lifetime. The metal is also reusable and endlessly recyclable.

Anodising and powdercoating

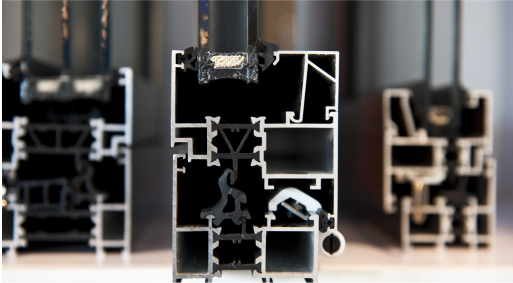

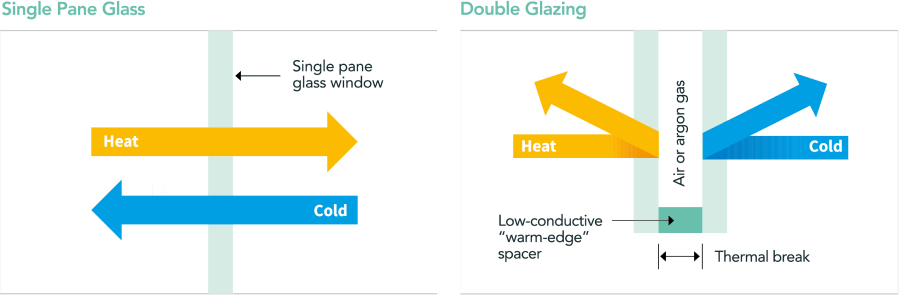

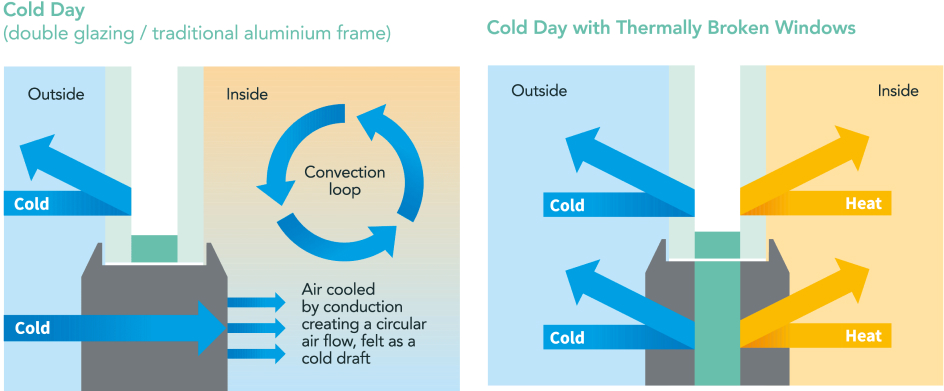

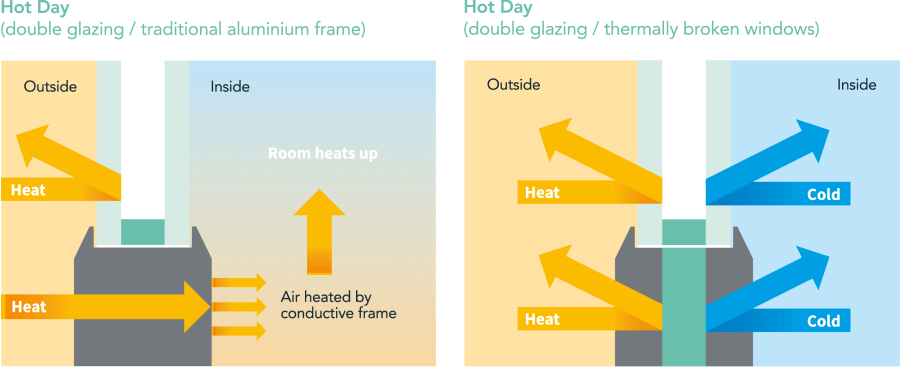

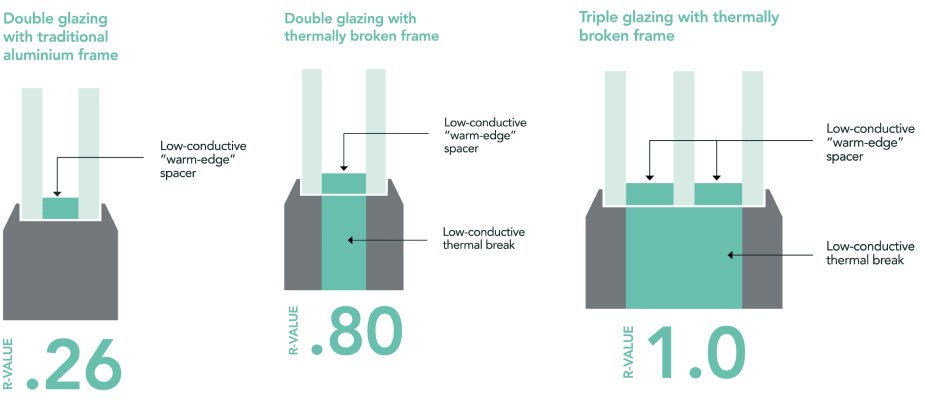

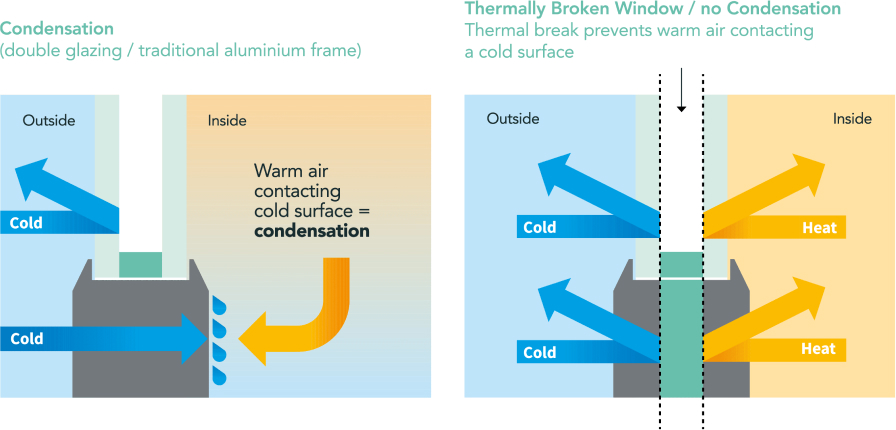

Thermal breaks

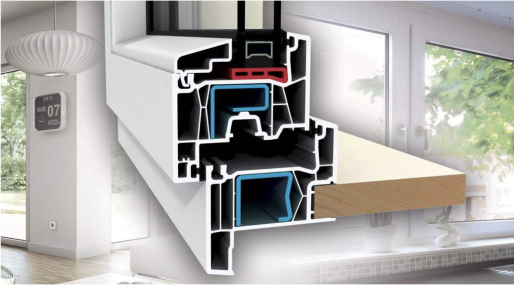

uPVC

uPVC (unplasticised polyvinyl chloride) is a naturally warm, easily cleaned material that is durable and resists chipping or splitting. A good insulating material, it aids home energy efficiency, and also reduces the risk of condensation forming on your window frames. To withstand wind loads, it is often reinforced with factory-fitted steel profiles. uPVC windows and doors are available with a variety of operational options, and in external finishes that stand up to harsher UV climates. Because it is unplasticised, uPVC is a more environmentally friendly polymer than PVC. It is easily recycled or downcycled into other products.

Overseas design influences

Timber

The traditional choice for pre-1970s homes in New Zealand, timber is aesthetically pleasing and can be painted or stained in any colour. Internal reveals – the parts of the frame on the interior of the window or door – are also typically made of wood, even on window frames of other materials. Native softwoods were generally used in early New Zealand homes, with more exotic options appearing in later decades.